I've been building a bare-bones harness for the '09. It has been stripped of unnecessary stuff and designed to integrate with the Vapor dash and HID headlights. That project has been on the back burner while I worked on the kick start stuff.

Now it looks like I'll put a Gen 1 ignition in the '09, so the bare bones harness will be modified to accommodate that stuff.

With thanks to Damocles for his help on the Gen 1 vs Gen 2 ignition differences, I think I have a plan. This still needs to be traced out at least two more times, but the scope of the project is set.

I'm going to pay a visit to Bothwell Automotive and see if they can balance a Gen 2 Rotor. I'll give it one shot. If they can I'll modify the Gen 2 rotor for use with the Gen 1 ignition. If not, I'll use the Gen 1 rotor.

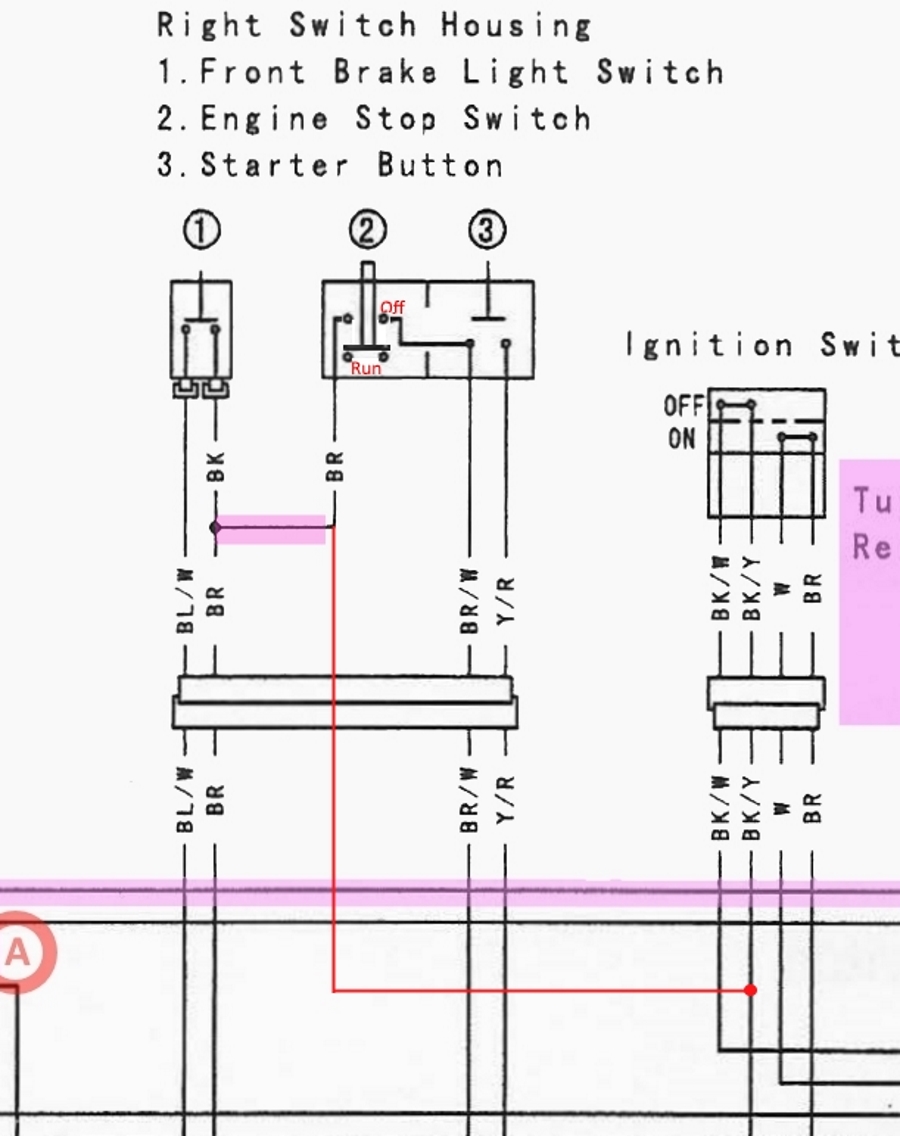

Here's my first crack at the modified wiring. Purple goes away, red is added.

![Image]()

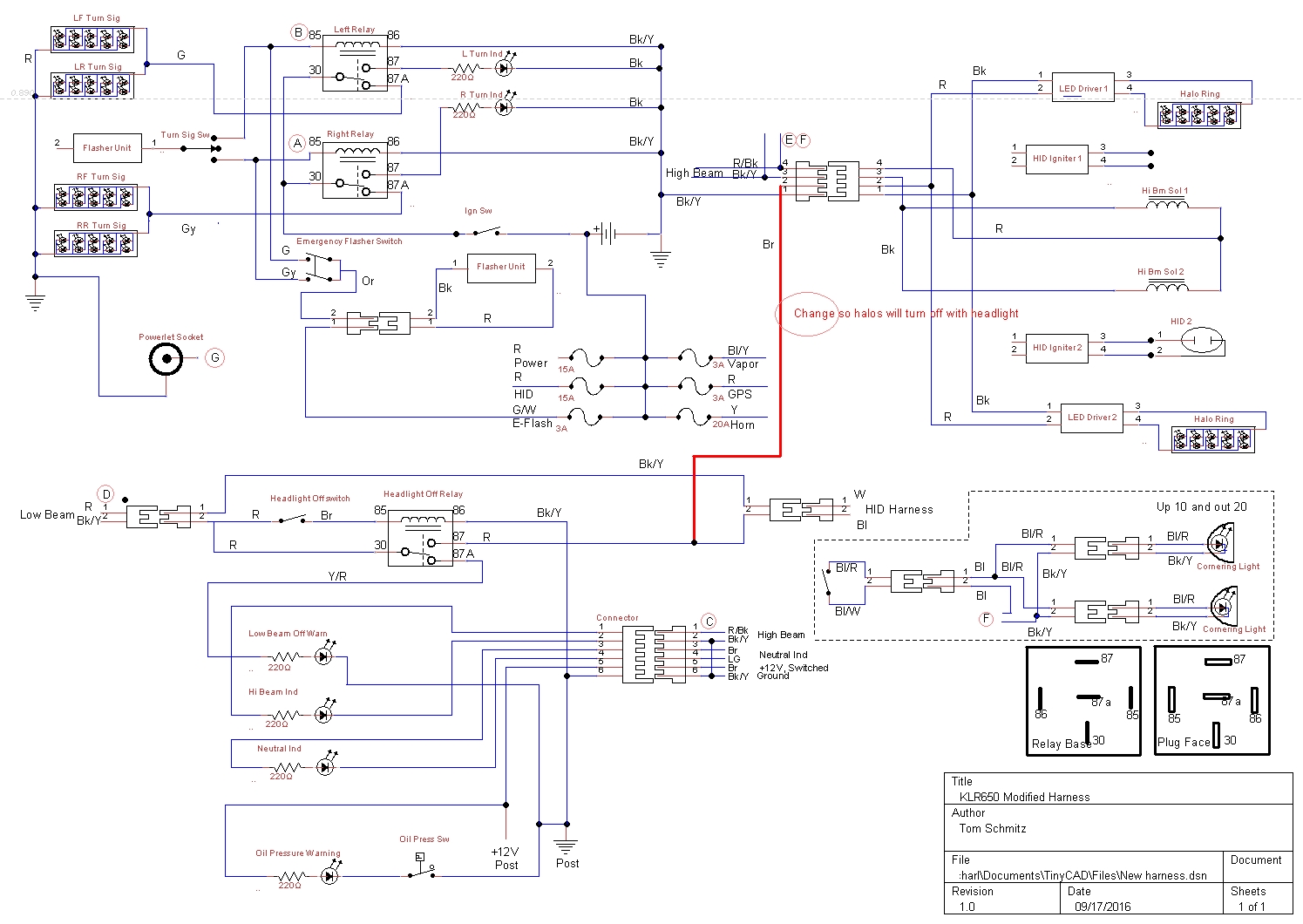

For competeness, this is the wiring diagram for all the new Vapor, HID, Turn/Emerg, etc that the harness interfaces with.

![Image]()

Now it looks like I'll put a Gen 1 ignition in the '09, so the bare bones harness will be modified to accommodate that stuff.

With thanks to Damocles for his help on the Gen 1 vs Gen 2 ignition differences, I think I have a plan. This still needs to be traced out at least two more times, but the scope of the project is set.

I'm going to pay a visit to Bothwell Automotive and see if they can balance a Gen 2 Rotor. I'll give it one shot. If they can I'll modify the Gen 2 rotor for use with the Gen 1 ignition. If not, I'll use the Gen 1 rotor.

Here's my first crack at the modified wiring. Purple goes away, red is added.

For competeness, this is the wiring diagram for all the new Vapor, HID, Turn/Emerg, etc that the harness interfaces with.